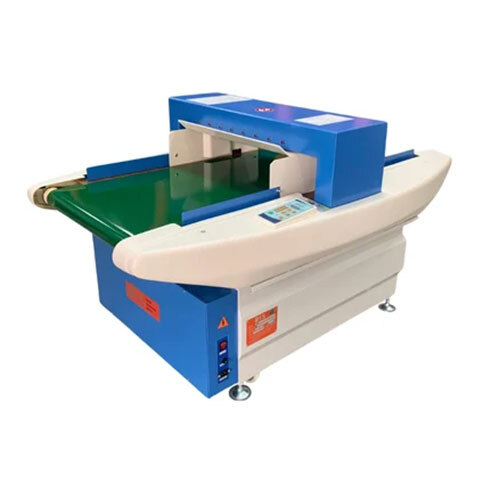

Four Wheel Belt Laminating Machine DTS-1265

Price 200000 INR/ Unit

MOQ : 1 Piece

Four Wheel Belt Laminating Machine DTS-1265 Specification

- Condition

- New

- Operate Method

- Electric

- Warranty

- 1 Year

- Product Type

- Four Wheel Belt Laminating Machine DTS-1265

- Voltage

- 440 V Volt (v)

Four Wheel Belt Laminating Machine DTS-1265 Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

About Four Wheel Belt Laminating Machine DTS-1265

The 4-Wheel Belt Pressing/Laminating Machine is a specialized piece of equipment primarily used in the leather belt manufacturing process. This machine is designed for laminating, bonding, and shaping leather belts and shoulder straps after the gluing phase. Its unique four-wheel design enhances the molding effect, ensuring a snug and precise fit.Laminating Function: The primary function of this machine is to laminate and bond leather belts and shoulder straps. It ensures that the glued layers adhere firmly and securely. Four-Wheel Design: The machines four-wheel bonding design plays a crucial role in shaping the belts. It improves the overall shaping effect and creates a better fit for the end product. Fast Operation: The machine is known for its fast operation, making it suitable for both mens and womens belts. It efficiently handles laminating tasks, even on belts with multiple joints.Advanced Lamination Efficiency

The DTS-1265 Four Wheel Belt Laminating Machine integrates automated technology for seamless, high-speed lamination. Designed using sturdy mild steel, it provides a stable and long-lasting operational life, suitable for demanding production lines.

Versatile and User-Friendly Operation

Equipped with a straightforward electric operation method, the machine allows users to handle both 220V and 440V voltages. Despite its advanced features, it remains easy to use and does not require computerization, making it accessible for businesses of all sizes.

Comprehensive Support and Assurance

Supplying the Indian market as an exporter, manufacturer, and more, we offer a 1-year warranty with every unit. Our service network ensures prompt support to maintain the machines peak efficiency and longevity.

FAQs of Four Wheel Belt Laminating Machine DTS-1265:

Q: How does the Four Wheel Belt Laminating Machine DTS-1265 operate?

A: This laminating machine works automatically using an electric drive, compatible with both 220V and 440V power supplies. Its control system is straightforward and does not require computerization, making setup and day-to-day operation simple and efficient.Q: What materials can be laminated using this machine?

A: The DTS-1265 is suited for a range of industrial lamination tasks, particularly on materials used in packaging and manufacturing. Its robust mild steel construction enables effective lamination of various substrates typically required in professional settings.Q: When should I perform maintenance on the DTS-1265 laminating machine?

A: Regular maintenance should be scheduled based on your usage volume, but its generally advisable to inspect moving belts and electrical components monthly. With its durable build, only basic routine care is needed, supported by the included 1-year warranty.Q: Where can the Four Wheel Belt Laminating Machine DTS-1265 be installed?

A: This machine is best suited for installation in industrial environments such as factories or workshops with standard 220V or 440V electrical connections. Its moderate weight ensures relative ease of relocation within a production floor.Q: What is the lamination process carried out by this machine?

A: The DTS-1265 uses an automated four-wheel belt system to evenly press and bond laminate layers onto the chosen substrate. The process ensures a smooth, consistent finish suitable for commercial applications.Q: How is this machine beneficial for businesses in India?

A: With its automatic operation, sturdy mild steel body, and adaptability to local voltage standards, the DTS-1265 enables Indian businesses to achieve faster output with minimal manual intervention. Its 1-year warranty and local service support further add to its value.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sewing Machine Category

Rotating Stitching Machine

Price 199000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Operate Method : Electric

Warranty : YES

Product Type : Rotating stitching machine

Needle Detector Machine DTS-1188

Price 190000 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Operate Method : Electric

Warranty : 1 Year

Product Type : Needle Detector Machine DTS1188

Computer Pattern Sewing Machine

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : Old

Operate Method : Electric

Warranty : YES

Vacuum Box Skiving Machine

Price 63600 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Operate Method : Electric

Warranty : 1 Year

Product Type : Vacuum Box Skiving Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese