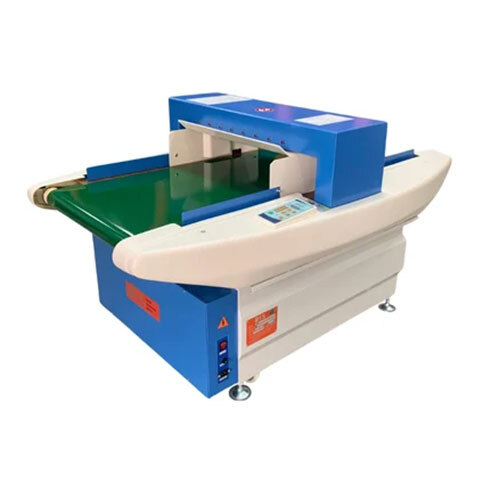

Needle Detector Machine DTS-1188

Price 190000 INR/ Unit

MOQ : 1 Piece

Needle Detector Machine DTS-1188 Specification

- Needle

- Detection for broken/missed needles

- Product Type

- Needle Detector Machine DTS-1188

- Dimension (L*W*H)

- 120 X 150 X 200MM Millimeter (mm)

- Color

- Grey / Blue

- Voltage

- 220V / 50Hz Volt (v)

- Operate Method

- Electric

- Warranty

- 1 Year

- Power

- 60W Watt (w)

- Condition

- New

- Body Material

- Heavy-duty metal & ABS

- Detection Area Width

- 600mm

- Metal Detected

- Ferrous metal

- Detection Sensitivity

- Fe≥0.8mm

- Conveyor Belt Speed

- approx. 25m/min

- Display Type

- Digital display

- Operation Temperature

- 0°C ~ 40°C

- Detection Method

- Magnetic induction (electromagnetic)

- Application

- Garment, Textile, Toy, Shoes, Bedding industries

- Alarm Method

- Buzzer, Light

Needle Detector Machine DTS-1188 Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

About Needle Detector Machine DTS-1188

The DTS-1188 Needle Detector Machine is used primarily in the textile and manufacturing industries to detect metal contaminants, such as needles or other metallic objects, that may be present in materials or products. High Sensitivity Detection: Capable of detecting even the smallest metal contaminants. Digital Display: Provides clear readouts and settings adjustments. Adjustable Sensitivity: Allows customization to detect various sizes of metal particles. Automatic Calibration: Ensures consistent and accurate detection. User-Friendly Interface: Simplifies operation with intuitive controls. Alarms and Indicators: Provides visual and audible alerts for detected contaminants. Data Logging: Records detection events for quality control and reporting.Advanced Electromagnetic Detection Technology

Equipped with magnetic induction (electromagnetic) technology, the DTS-1188 delivers highly sensitive detection specifically for ferrous metals such as broken or missed needles. This makes it an indispensable tool in ensuring product safety and maintaining quality standards across garment, textile, toy, and footwear manufacturing.

Robust Construction, Reliable Operation

Built from heavy-duty metal and ABS, the DTS-1188 is engineered for longevity and resilience in demanding industrial environments. Its wide detection area and stable conveyor belt speed allow for efficient inspection of large batches. Integration of digital display, buzzer, and light alarms further simplify the operation process.

User-Friendly Features and Versatile Application

With an easy-to-read digital display and intuitive electric operation, the DTS-1188 ensures seamless usability. Its versatility extends across multiple industries, making it a practical investment for exporters, importers, manufacturers, service providers, and suppliers seeking reliable inspection solutions.

FAQs of Needle Detector Machine DTS-1188:

Q: How does the Needle Detector Machine DTS-1188 identify broken or missed needles?

A: The DTS-1188 uses magnetic induction (electromagnetic) detection to sense ferrous metal fragments, such as broken or missed sewing needles, passing through its 600mm wide inspection area.Q: What types of materials and industries is the DTS-1188 suitable for?

A: This machine is ideal for the garment, textile, toy, shoe, and bedding industriesenabling efficient inspection of products to ensure they are free of hazardous needle fragments.Q: When should the DTS-1188 be used in the production process?

A: It should be deployed after the sewing or production phase but before final product packaging, to ensure all items are thoroughly checked for broken or missed needles.Q: Where can I install the DTS-1188 in my facility?

A: You can place the machine at the end of the production line or before the packaging section, ensuring seamless integration and easy access for quality control checks.Q: What are the key benefits of using the DTS-1188 needle detector?

A: This machine significantly reduces the risk of defective products reaching customers, enhances product safety, streamlines quality control, and helps maintain compliance with industry safety standards.Q: How can operators know if a needle fragment is detected?

A: Whenever the detector senses a ferrous metal object, it triggers both a buzzer and a light alarm, making it instantly noticeable for operators.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sewing Machine Category

Zig zag Sewing Machine

Price 60000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : YES

Operate Method : Manual

Condition : New

Color : OffWhite

Double Thread Seated Type Lock Stitch Stitcher Machine

Price 560000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : YES

Operate Method : Electric

Condition : New

High Speed Bending Arm Zigzag Sewing Machine

Price 190000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : YES

Operate Method : Electric

Condition : New

Color : White

High Speed Single Presser Foot Sewing Machine

Minimum Order Quantity : 1 Unit

Warranty : YES

Operate Method : Automatic

Condition : New

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese