Price 1520000 INR/ Unit

MOQ : 1 துண்டு

Specification

- ஊசி

- DP x 5

- உத்தரவாதத்தை

- 1 Year

- ஊட்ட பொறிமுறை

- Compound Feed

- தையல் வேகம்

- 1200 S.P.M.

- தைத்து நீளம்

- Up to 12 mm

- கலர்

- Blue

- கண்டிஷன்

- மின்னழுத்த

- வோல்ட் (வி)

- பவர்

- 0.75 kW

- தைத்து உருவாக்கம்

- Lock Stitch

- இயக்கு முறை

- தயாரிப்பு வகை

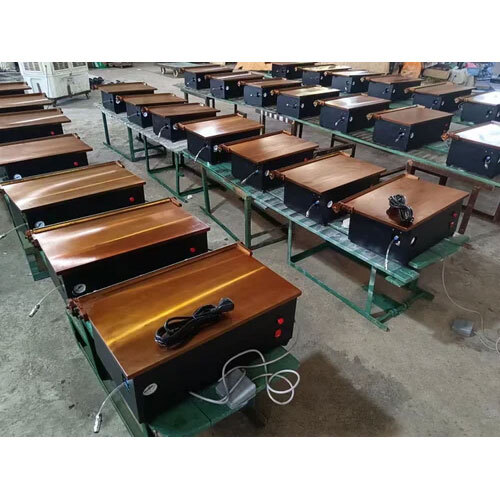

- SOLE STITCHING MACHINE DTS-828

- தையல் தடிமன்

- Up to 30 mm

- தைத்து அகலம்

- Up to 19 mm

Trade Information

- Minimum Order Quantity

- 1 துண்டு

- வழங்கல் திறன்

- மாதத்திற்கு

- டெலிவரி நேரம்

- நாட்கள்

About

- High Accuracy: Designed for precise stitching to securely attach soles to the shoe uppers, ensuring a robust bond and enhancing the shoes durability.

- Multiple Stitching Options: Often supports various types of stitching patterns and techniques, including single, double, or triple stitching, depending on the shoe design and requirements.

- Automated Functions: Many models, including the DTS-828, feature automated functions for faster and more efficient stitching, reducing manual effort and increasing production speed.

- Adjustable speed settings to accommodate different stitching requirements and ensure optimal performance.

- Control Panel: Equipped with an easy-to-use control panel for setting stitching parameters, monitoring operations, and making adjustments as needed.

- Ergonomic Design: Designed for operator comfort, with controls and components positioned for easy access and minimal strain during operation.

Heavy-Duty Construction and Performance

Built with a cast iron body for long-term durability, the DTS-828 excels in heavy industrial environments. Its compound feed mechanism and clutch motor allow efficient, stable operation at high speeds. Designed for manufacturers requiring a dependable and robust sole stitching solution, its large bobbin capacity further enhances productivity by reducing the frequency of bobbin changes.

Precision Stitching for Thick Materials

The DTS-828 can stitch footwear soles up to 30 mm thick with precision. Its lock stitch mechanism ensures strong, consistent seams, and the wide stitch width and length accommodate a variety of shoe designs. Ideal for handling tough leather and dense materials, the machines advanced features guarantee high-quality results for both exporters and service providers.

FAQs of SOLE STITCHING MACHINE DTS-828:

Q: How does the DTS-828 maintain a consistent stitch quality on thick shoe soles?

A: The DTS-828 utilizes a compound feed mechanism and lock stitch formation, providing stable fabric movement and secure stitches on materials up to 30 mm thick. This ensures uniform stitching quality even with challenging or dense materials used in footwear manufacturing.Q: What are the benefits of the semi-automatic oil lubrication system?

A: The semi-automatic oil system helps maintain smooth operation and reduces wear on moving parts. It minimizes manual maintenance, extends the machines lifespan, and ensures continuous production with fewer interruptions for oiling.Q: When should I perform maintenance on this machine?

A: Basic cleaning and inspection should occur daily after use, while oil lubrication checks should be done weekly. Consult the user manual for a full maintenance schedule, and ensure all procedures are followed to enjoy the 1-year warranty coverage.Q: Where is the DTS-828 suitable for installation?

A: This machine, with dimensions of 1200 mm x 650 mm x 1160 mm and a heavy-duty cast iron body, is best suited for dedicated manufacturing facilities or workshops involved in footwear production, especially where consistent heavyweight stitching is required.Q: What is the process for threading the large capacity bobbin?

A: Threading the DTS-828s bobbin involves removing the bobbin case, inserting the thread, and securing it as per the illustrated instructions in the manual. The large bobbin reduces loading frequency, supporting long periods of uninterrupted stitching.Q: How does the low noise operation benefit workshop environments?

A: Low noise operation creates a more comfortable and productive work environment, reducing fatigue for operators and improving communication in busy manufacturing settings.Q: What is included in the one-year warranty for the DTS-828?

A: The one-year warranty covers manufacturing defects and malfunctions, provided the machine is operated and maintained according to the manufacturers guidelines.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

மேலும் Products in தையல் இயந்திரம் Category

கணினி நேரடி டிரைவிங் ஒற்றை ஊசி தையல் மெஷின்

விலை அல்லது விலை வரம்பு : ரூபாய்

விலை அலகு : அலகுகள்/அலகுகள்

குறைந்தபட்ச ஆர்டர் அளவு : 1

கண்டிஷன் : புதியது

அளவின் அலகு : அலகுகள்/அலகுகள்

இயக்கு முறை : எலக்ட்ரிக்

இரட்டை நூல் பூட்டு தைத்து அமர்ந்து தையல் மெஷின்

விலை அல்லது விலை வரம்பு : ரூபாய்

விலை அலகு : அலகுகள்/அலகுகள்

குறைந்தபட்ச ஆர்டர் அளவு : 1

கண்டிஷன் : புதியது

அளவின் அலகு : அலகுகள்/அலகுகள்

இயக்கு முறை : எலக்ட்ரிக்

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு எஸ்எம்எஸ் அனுப்பவும்

எஸ்எம்எஸ் அனுப்பவும் என்னை இலவசமாக அழைக்கவும்

என்னை இலவசமாக அழைக்கவும் English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese